Physico Chemical Testing: Ensuring Product Quality and Safety Across Industries

When it comes to understanding the quality and safety of products, physico chemical testing stands out as a crucial process. I rely on these tests to reveal the physical and chemical properties that define everything from water and food to pharmaceuticals and cosmetics. It’s amazing how a few precise measurements can ensure products meet strict standards and keep us safe.

I’ve seen how industries depend on accurate physico chemical testing not just for compliance but also for building trust with customers. Whether I’m checking the purity of drinking water or the stability of a new skincare formula, these tests offer the insights I need to make informed decisions. It’s clear that mastering physico chemical testing is key to maintaining quality in today’s fast-paced market.

What Is Physico Chemical Testing?

Physico chemical testing refers to analytical methods that measure the physical and chemical properties of substances. I use these tests to quantify parameters like pH, turbidity, conductivity, moisture content, and chemical composition. Laboratories apply physico chemical testing for water, food, pharmaceuticals, cosmetics, and industrial materials.

I rely on physico chemical testing to identify contaminants, validate product consistency, and ensure regulatory compliance. Measurement of variables such as dissolved oxygen in water, active ingredient concentration in pharmaceuticals, and heavy metal levels in cosmetics demonstrates the test’s broad scope.

Common Physico Chemical Parameters

| Parameter | Example Material | Primary Measurement | Regulatory Reference |

|---|---|---|---|

| pH | Drinking water | Acidity/Alkalinity | WHO Guidelines (2022) |

| Conductivity | Industrial effluent | Ionic content | EPA 40 CFR Part 136 |

| Moisture Content | Tablets | Water percent | USP <921> |

| Turbidity | Bottled water | Cloudiness (NTU) | EPA National Primary Standards |

| Chemical Oxygen Demand (COD) | Wastewater | Oxidizable pollutants | ISO 6060 |

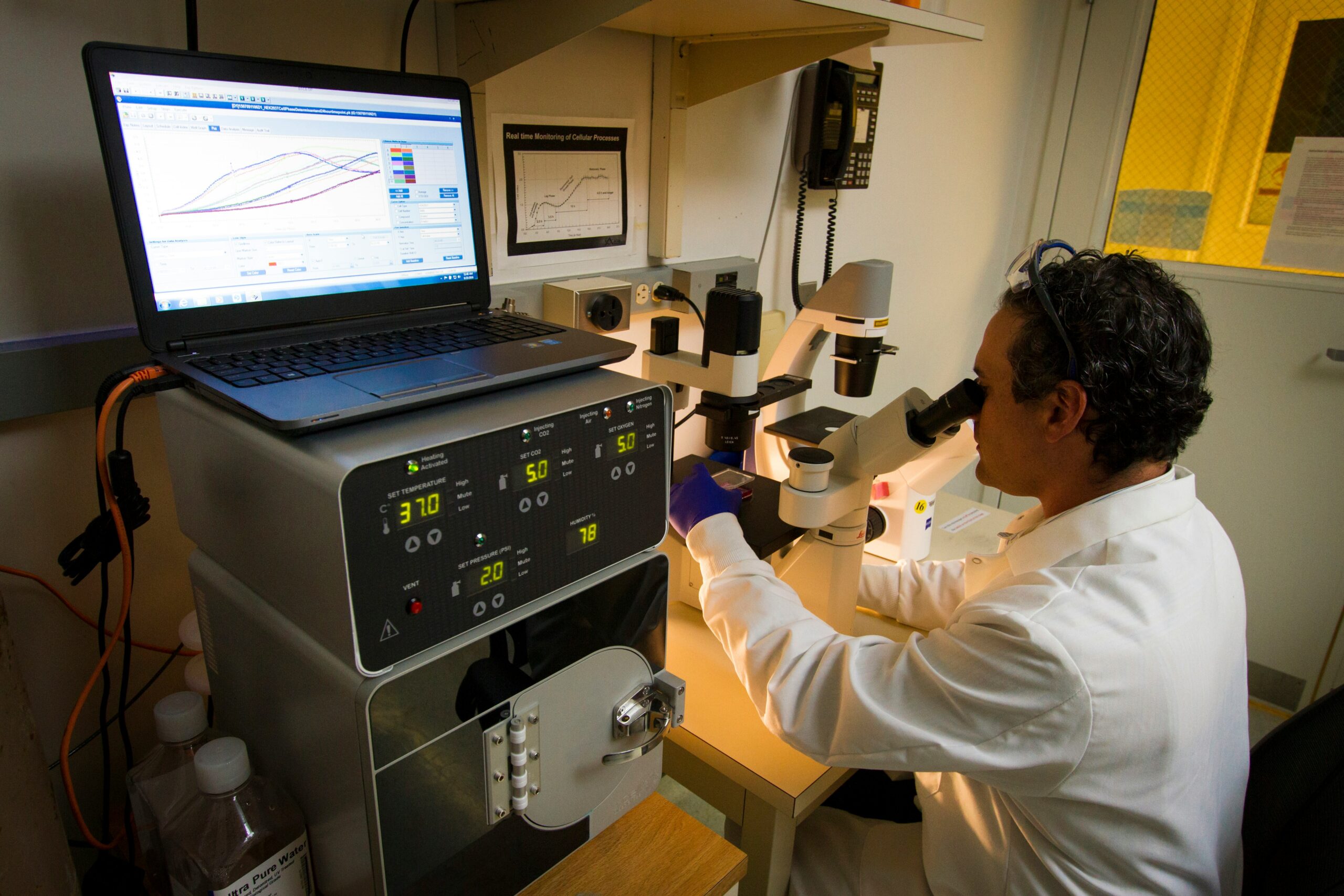

Role in Quality Control

I integrate physico chemical testing in quality control processes to verify product standards and detect deviations. Instrumentation such as pH meters, spectrophotometers, and titrators provides reproducible and traceable results. Results determine if products like bottled water meet purity requirements or if cosmetic creams maintain specified ingredient ranges.

Regulatory Considerations

Testing protocols follow regulations set by organizations like the U.S. Environmental Protection Agency (EPA), United States Pharmacopeia (USP), and the World Health Organization (WHO). I ensure compliance by referencing specific methods and maximum limits detailed in official standards.

Example: Physico Chemical Testing in Water Treatment

| Test | Target Value (Drinking Water) | Detection Method |

|---|---|---|

| pH | 6.5–8.5 | pH Meter |

| Turbidity | <1 NTU | Nephelometer |

| Conductivity | <2500 µS/cm | Conductivity Meter |

Physico chemical testing helps manage water quality in treatment plants by targeting key utility standards. Measurements enable operators to adjust processes and maintain compliance with health guidelines.

Importance of Physico Chemical Testing in Various Industries

Physico-chemical testing supports industry-specific compliance and product consistency. I use these tests to verify regulatory adherence and confirm product quality in critical sectors.

Role in Food and Beverage Industry

Physico-chemical testing ensures food and beverage manufacturers deliver safe and consistent products. I monitor parameters such as pH, moisture, and contaminants to validate shelf life, detect adulteration, and control process quality. For example, pH values in dairy, moisture content in baked goods, and residual chlorine in beverage production require strict limits according to FDA and Codex standards.

| Parameter | Typical Range | Example Product | Regulatory Reference |

|---|---|---|---|

| pH | 4.6–6.8 | Cheese, Yogurt | FDA |

| Moisture (%) | 12–18 | Bread | Codex Alimentarius |

| Salt (%) | 1.5–2.5 | Cured Meats | USDA |

Applications in Pharmaceuticals

Pharmaceutical quality assurance depends on physico-chemical testing for ingredient verification and contamination prevention. I rely on validated protocols to assess properties like melting point, solubility, and particulate matter in finished drugs. The USP and ICH Q6A guidelines specify these values to manage purity, batch consistency, and therapeutic safety.

| Test | Critical Value | Application Area | Regulatory Body |

|---|---|---|---|

| Melting Point | 168–174°C | Active Ingredients | USP |

| Residue on Ignition (%) | ≤0.1 | Tablets, Capsules | ICH Q6A |

| pH (liquids) | 3.0–8.0 | Syrups, Injections | USP |

Environmental and Water Quality Monitoring

Physico-chemical analysis enables detection of pollutants and assurance of potable water standards. I utilize these tests in municipal water labs and industrial discharge management, measuring parameters like turbidity, conductivity, dissolved oxygen, and heavy metals. EPA, WHO, and local agencies set permissible limits for each contaminant.

| Parameter | Regulatory Limit (mg/L or NTU) | Monitoring Context | Standard Reference |

|---|---|---|---|

| Total Dissolved Solids (TDS) | ≤500 mg/L | Drinking Water | EPA, WHO |

| Turbidity | ≤1 NTU | Water Treatment Plants | EPA |

| Lead | ≤0.015 mg/L | Tap Water | EPA, WHO |

Key Parameters Measured in Physico Chemical Testing

I quantify core attributes in physico-chemical testing to ensure regulatory and safety benchmarks in products. Key indicators like pH, conductivity, moisture, ash value, and toxic elements support precise quality assessments.

pH and Conductivity

I use pH measurement to determine hydrogen ion concentration in a sample, tracking acidity or alkalinity. For example, water and soft drinks require pH control to meet EPA and FDA limits; the EPA specifies a range of 6.5–8.5 for drinking water (EPA, 2023). Conductivity measures ionic strength and dissolved salts, with applications in evaluating water purity, pharmaceutical ingredients, and beverage consistency. Low conductivity suggests fewer ionic impurities, aligning with pharmaceutical and cosmetic standards.

| Parameter | Example Industry | Typical Range | Regulatory Reference |

|---|---|---|---|

| pH | Drinking water | 6.5–8.5 | EPA |

| Conductivity | Pharmaceuticals | <2.1 µS/cm | USP |

| pH | Soft drinks | 2.5–5.0 | FDA |

Moisture Content and Ash Value

I assess moisture content to verify product stability and shelf life, focusing on foods, powders, and pharmaceuticals. Reduced water activity prolongs shelf life and prevents spoilage. For example, milk powders must contain less than 5% moisture (Codex Alimentarius). Ash value quantifies inorganic mineral content; I use this to monitor purity and detect adulteration. The food industry and pharmaceuticals both define max ash contents for compliance.

| Parameter | Example Product | Maximum Limit | Regulatory Reference |

|---|---|---|---|

| Moisture | Milk powder | <5% | Codex Alimentarius |

| Ash | Wheat flour | <0.65% (dry basis) | FDA |

| Moisture | Tablets | <3% | USP |

Heavy Metals and Toxins

I rely on targeted tests to identify and quantify heavy metals like lead, cadmium, arsenic, and mercury, which pose significant health risks. The pharmaceutical and food industries specify strict permissible limits, such as <10 ppb lead in drinking water (EPA) and <1 ppm arsenic in rice (FDA). Toxin analysis extends to pesticides, mycotoxins, and industrial contaminants to maintain product safety.

| Heavy Metal/Toxin | Product | Maximum Allowable Limit | Regulatory Reference |

|---|---|---|---|

| Lead | Drinking water | <10 ppb | EPA |

| Arsenic | Rice | <1 ppm | FDA |

| Mercury | Fish | <1 ppm | WHO |

| Aflatoxin | Peanuts | <20 ppb | Codex Alimentarius |

Common Methods Used in Physico Chemical Testing

Physico-chemical testing relies on several key analytical methods to measure physical and chemical parameters in products and environmental samples. I employ selected techniques based on the specific attributes I need to quantify and the regulatory standards that apply.

Titration and Spectroscopy Techniques

I use titration and spectroscopy to determine concentrations of analytes in samples precisely.

- Titration methods assess chemical reactivity, like acidity, alkalinity, or specific ion content, using indicators for endpoint detection.

- Spectroscopy techniques, including UV-Visible, Atomic Absorption (AAS), and Infrared (IR), quantify concentrations of metals, organic compounds, and molecular structures by analyzing light absorption or emission at specific wavelengths.

| Technique | Measured Parameters | Typical Applications | Regulatory Reference |

|---|---|---|---|

| Acid-Base Titration | Acidity, Alkalinity | Water, food, pharmaceuticals | USP, FDA, EPA |

| AAS | Lead, Mercury, Cadmium | Water, food, pharmaceuticals | EPA, WHO, Codex |

| UV-Vis Spectroscopy | Nitrate, Phosphate, Iron | Water treatment, food additives | EPA, ISO |

Chromatography

I use chromatography to separate and quantify individual components in complex mixtures.

- Gas Chromatography (GC) identifies and measures volatile organic compounds, like pesticide residues or flavorings in food processing.

- High-Performance Liquid Chromatography (HPLC) detects compounds in pharmaceuticals, drinks, and environmental pollutants, offering high sensitivity and specificity.

Regulatory agencies like the FDA and USP reference GC and HPLC for required analyses in official compendia.

| Chromatography Type | Main Use | Common Analytes | Regulatory Reference |

|---|---|---|---|

| GC | Volatile compound detection | Alcohols, solvents, pesticides | FDA, USP |

| HPLC | Non-volatile compound analysis | Drug actives, mycotoxins, dyes | USP, ICH Q6A |

Gravimetric Analysis

Gravimetric analysis measures the mass of analytes after chemical transformation or separation.

- I quantify parameters like total dissolved solids, moisture content, and ash value using desiccation or incineration.

- These measurements provide high accuracy for purity and content evaluations in food, water, and pharmaceutical products.

Established standards, such as those outlined in AOAC methods and pharmacopeias, confirm relevance.

| Analyte | Gravimetric Procedure | Typical Matrix | Key Standard Reference |

|---|---|---|---|

| Moisture Content | Drying at 105°C | Grains, tablets | AOAC, USP |

| Ash Value | Incineration at 550°C | Tea, spices, drugs | AOAC, ISO |

| Total Solids | Evaporation/Drying | Drinking water | EPA, APHA |

Challenges and Best Practices in Physico Chemical Testing

Common Challenges in Physico Chemical Testing

- Instrument Calibration:

Accurate physico-chemical testing depends on routine calibration of analytical equipment like pH meters and spectrophotometers; instrument drift or neglected maintenance introduces measurement bias.

- Sample Contamination:

Physico-chemical parameters like moisture and ash value vary due to sample contamination from improper collection or storage, as outlined by USP <1225>.

- Standardization of Methods:

Method variations generate inconsistent results across test sites; harmonization under ISO/IEC 17025 reduces this variability.

- Complex Matrices:

Food, pharmaceutical, and environmental samples contain interfering substances complicating analyses, especially in detecting trace elements.

- Regulatory Compliance:

Strict limits set by authorities such as the EPA and FDA require documentation and rapid response when values exceed thresholds.

Best Practices to Enhance Reliability

- Routine Quality Assurance:

Implementing internal quality controls and regular proficiency testing ensures ongoing validity for physico-chemical results.

- Reference Materials:

Using traceable reference standards aligns with ISO and ASTM guidelines, supporting method verification and bias correction.

- Sample Handling Protocols:

Following good laboratory practice (GLP) minimizes degradation; for example, sealing samples for moisture analysis to prevent atmospheric exposure.

- Staff Training:

Ongoing technical training for analysts on physiochemical methods and regulatory updates maintains method accuracy and regulatory alignment.

- Validation and Auditing:

Periodic validation and external audits verify that instruments and procedures meet compliance per FDA and ICH requirements.

Physico Chemical Testing: Key Challenges and Mitigating Strategies

| Challenge | Example (Matrix) | Mitigating Practice | Source/Standard |

|---|---|---|---|

| Calibration errors | pH in water | Schedule monthly calibration checks | EPA 150.1 |

| Sample contamination | Ash in milk | Use sterile collection containers | USP <1225> |

| Method inconsistency | Conductivity test | Adopt ISO/IEC 17025 procedures | ISO/IEC 17025 |

| Regulatory threshold breach | Lead in cosmetics | Immediate investigation and retest | FDA Q3D |

| Analytical interference | Pesticides in tea | Matrix-matched calibration | ICH Q2(R1) |

Best Practices in Physico-Chemical Testing for Casino Beverage Service

- Quality Control of Casino Beverages:

Regular physico-chemical analysis of water and mixers used in casino bars detects contaminants like heavy metals or microbial residues, addressing regulatory mandates from bodies like the FDA for onsite beverage safety.

- Rapid Onsite Testing:

Employing portable analyzers for immediate pH and conductivity checks in casino bar operations reduces the risk of serving substandard products.

| Beverage Parameter | Standard Value | Common Issue | Mitigation Practice |

|---|---|---|---|

| pH of bottled water | 6.5–8.5 (EPA) | Acidic shift | Daily meter calibration |

| Conductivity (Soda) | 150–1,500 µS/cm | Syrup dilution error | Matrix standardization |

| Moisture (Juices) | <10% (Codex) | Evaporation | Seal containers post-open |

Physico-chemical testing aligns beverage safety with broader casino operational quality standards, reinforcing compliance and building customer trust.

Conclusion

Physico-chemical testing plays a vital role in protecting public health and supporting industry standards. I’ve seen firsthand how investing in robust testing processes pays off by minimizing risks and building lasting consumer confidence.

Staying updated on evolving regulations and best practices is essential. I always recommend prioritizing staff training and equipment maintenance to keep testing accurate and reliable. With a proactive approach, it’s possible to meet regulatory demands and deliver safe, high-quality products every time.

Frequently Asked Questions

What is physico-chemical testing?

Physico-chemical testing involves measuring the physical and chemical properties of materials, such as pH, turbidity, conductivity, and chemical composition. These tests are essential for ensuring product quality, safety, and regulatory compliance across industries like water, food, pharmaceuticals, and cosmetics.

Why is physico-chemical testing important for product quality?

Physico-chemical testing helps detect contaminants, assess consistency, and verify that products meet established safety and quality standards. By providing accurate measurements, it ensures products are safe for consumers and comply with regulations, fostering customer trust.

Which industries rely on physico-chemical testing?

Industries such as food and beverage, pharmaceuticals, cosmetics, environmental monitoring, and water treatment rely on physico-chemical testing to maintain quality, ensure safety, and adhere to regulatory requirements.

What are common parameters measured in physico-chemical testing?

Typical parameters include pH, conductivity, moisture content, turbidity, ash value, and the presence of toxic elements like heavy metals. These measurements provide insights into product composition, purity, and safety.

What instruments are used for physico-chemical testing?

Common instruments include pH meters, spectrophotometers, conductivity meters, and moisture analyzers. These tools help obtain precise, reproducible measurements of key product attributes.

How does physico-chemical testing help with regulatory compliance?

Testing ensures products meet standards set by regulatory authorities like the FDA, EPA, USP, WHO, and Codex. Compliance helps avoid penalties, supports market access, and assures consumers of product safety.

What challenges are faced in physico-chemical testing?

Challenges include instrument calibration errors, sample contamination, method standardization issues, and keeping up with changing regulatory standards. Proper staff training and quality assurance are essential in overcoming these challenges.

What best practices improve reliability in physico-chemical testing?

Best practices include regular instrument calibration, use of certified reference materials, proper sample handling, routine staff training, and rigorous validation and auditing procedures.

How is physico-chemical testing used in the food and beverage industry?

It monitors key parameters such as pH and moisture content to ensure product safety, consistency, and compliance with standards set by authorities like the FDA and Codex.

Why is physico-chemical testing significant in the casino beverage industry?

Regular analysis of water and mixers in casinos helps detect contaminants and maintain beverage quality, ensuring compliance with FDA regulations and building customer trust through consistent product safety.